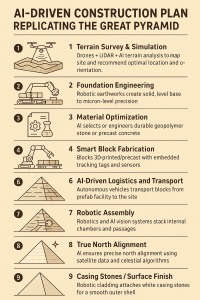

How AI Could Rebuild the Great Pyramid of Giza — Step by Step

The Great Pyramid of Giza stands as one of the most extraordinary feats of engineering in human history. Built over 4,500 years ago with over 2 million limestone blocks, its precision and scale continue to mystify engineers and historians alike.

But what if we had to replicate it today? And what if we let artificial intelligence take the lead?

This blog explores a step-by-step, AI-driven plan to rebuild the Great Pyramid using modern materials, robotics, and sustainable tech — all while preserving its durability, astronomical precision, and iconic structure.

Total Estimated Timeline: 18–36 months

Step 1: Terrain Survey & Simulation (2–4 weeks)

AI-controlled drones and LIDAR systems would scan vast areas to identify an optimal construction site. This includes:

-

Geotechnical analysis for stability

-

Assessment of solar exposure and celestial alignments

-

Topographical mapping to the centimeter

AI output: A 3D terrain model with a recommended orientation (precise cardinal north alignment, just like the original).

Step 2: Foundation Engineering (1–2 months)

The original pyramid sat on leveled bedrock. To replicate this:

-

AI designs a multi-layered, compacted foundation using modern drainage and vibration resistance principles

-

Robotic earthmovers and graders prepare the base with micron-level precision

Result: A foundation as solid as the one beneath the Giza Plateau — but with enhanced weatherproofing.

Step 3: Material Optimization (3–6 weeks)

AI simulations test thousands of possible material combinations to find the most durable, cost-effective, and sustainable alternative to limestone and granite.

Most likely choice:

-

Geopolymer stone blocks or

-

High-performance precast concrete

These materials replicate the look and feel of ancient stone while being easier to cast, transport, and place.

Step 4: Smart Block Fabrication (6–9 months)

This is where AI meets industry 4.0:

-

Blocks are 3D-printed or precast in a nearby facility

-

Each block includes tracking tags, micro sensors, or even internal reinforcement

-

Designed to interlock with minimal mortar, ensuring structural integrity

The pyramid required over 2 million blocks. Modern automation could produce 5,000–10,000 per day depending on scale.

Step 5: AI-Driven Logistics & Transport (Ongoing during fabrication)

AI orchestrates delivery from the prefab site to the build location:

-

Autonomous trucks or drones deliver blocks in optimal sequence

-

Traffic, terrain, and scheduling are constantly recalculated in real-time

Efficiency boost: Reduced idle time and material waste, with intelligent rerouting for weather or mechanical issues.

Step 6: Robotic Assembly (12–18 months)

Here’s the heart of the build:

-

Robotic cranes, arms, or swarm robots stack blocks with laser-guided precision

-

AI constantly analyzes placement errors and makes on-the-fly corrections

-

Chambers, tunnels, and shafts are pre-designed and integrated layer by layer

This drastically cuts labor hours and virtually eliminates human error.

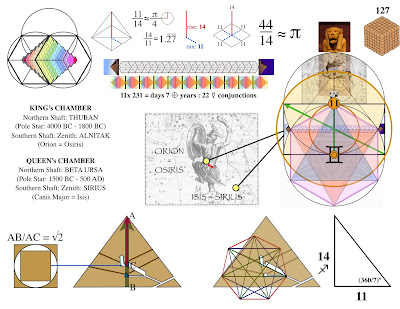

Step 7: True North Alignment (Built-in from Day One)

The Great Pyramid is aligned with less than 0.05° deviation from true north — a feat difficult even today.

With AI-guided:

-

GNSS systems

-

Gyroscopes

-

Astronomical modeling

We can achieve even higher alignment precision, ensuring the pyramid honors its ancient astronomical significance.

Step 8: Casing Stones & Surface Finish (1–2 months)

To replicate the pyramid’s original gleam:

-

Robotic cladding systems attach polished white geopolymer or limestone panels

-

Smooth joins and consistent angle slopes are calculated in real-time by AI

While this step is cosmetic, it adds a layer of authenticity — and weather protection.

Step 9: Final Inspection & Calibration (2–3 weeks)

AI performs a complete audit:

-

Thermal imaging scans for structural voids

-

Ultrasonic and stress tests on internal chambers

-

Cross-checks with 3D models for placement tolerances

If needed, robots adjust block positions or reseal microcracks.

Result: A structure as perfect as technology can produce — arguably more precise than the original.

Why Use AI to Rebuild the Pyramid?

This approach:

-

Slashes construction time from decades to under 3 years

-

Uses sustainable materials with low energy cost

-

Ensures millimeter precision and astronomical alignment

-

Minimizes human risk in heavy lifting and desert conditions

-

Could make ancient mega-structures replicable anywhere in the world

Final Thoughts

What was once a nearly mythical feat of ancient engineering could soon be within reach — thanks to AI and advanced robotics.

Whether for historical education, tourism, or just the awe of seeing such monuments re-imagined, AI gives us tools the ancient builders never had — but the vision and ambition remain timeless.